Unfinished Furniture of Leesville, Louisiana - Quality Wood Furniture!

Unfinished Furniture is all about value, customization and personal expression!

Welcome to Quality Wood Furniture! We sell a complete line of unfinished and finished furniture, constructed from a variety of quality woods in multiple styles. Furnish your home from a selection of quality wood furniture including chairs, rockers, desks, book cases, tables, computer furniture, juvenile furniture, home entertainment centers, cabinets, bedroom furniture, dining room furniture, storage units, and accessories. We also carry the finest wood finishes and wood stains available. Plus we'll help you get just the custom look you want for your new furniture! Check our online finishing tips and furniture care resources. And follow the links to see our online furniture showroom. Then come and visit us! Your home is a reflection of who you are - just imagine the possibilities with unfinished furniture. Real wood furniture, the solid choice!

Accessories

Accessories Bedroom

Bedroom Benches/Chest

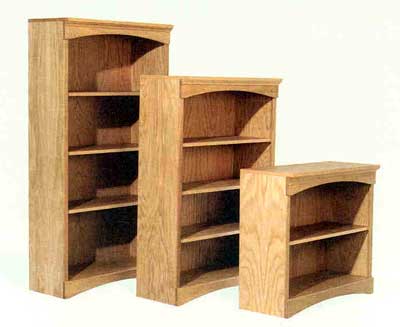

Benches/Chest Bookcases

Bookcases Children's

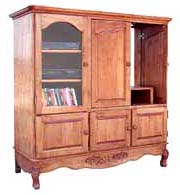

Children's Entertainment

Entertainment Kitchen/Dining

Kitchen/Dining Living/Family

Living/Family Office

Office Outdoor

Outdoor